The practice of achieving optimal buffet temperature begins well before guests start opening lids for their first view. A ceramic chafing dish maintains heat well when you employ certain tested methods. Guidance provided below provides methods for food safety and temperature adherence and prolongs the lifespan of your ceramic buffet dishes.

Why a Ceramic Chafing Dish Holds Heat Better

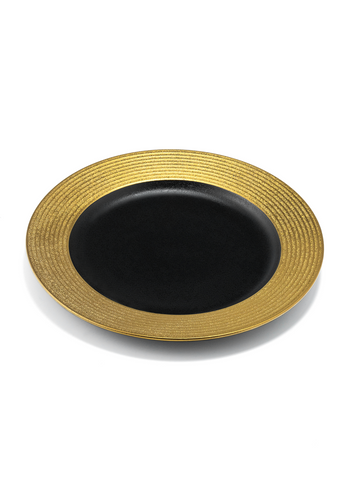

The dense construction of ceramic traps heat which then releases slowly because its walls do not experience rapid temperature changes that occur in stainless-steel pans. Acidic sauces maintain their original flavors when using the non-reactive glazed surface and the gleaming exterior enhances wedding and brunch and home party table settings. Ceramic heat holders provide seamless steady heat distribution while maintaining high-class look quality which makes them the top professional choice for combined requirements.

Preparation Begins with Proper Preheating

Temperature-stranded food receives no benefit from adding this item to casual kitchen temperature.

- Placing an empty insert inside a 175 °F (80 °C) oven for 15 minutes will prepare it.

- For limited oven capacity use boiling water to heat the dish by covering it before allowing ten minutes of rest before removing the water.

Heat application methods by either oven or boiling water enable ceramics to become heat reservoirs that feed your dinner dishes instead of draining their temperature.

Choose appropriate heat sources which match the duration of your event

The fuel you select depends on the nature of your social gathering.

- Gel fuel cans ignite swiftly but offer two hours of burning time that is suitable for light brunch catering and hors d'oeuvre displays.

- The Wick-style liquid fuel system provides long-lasting and even flames across six hours thus becoming the fundamental source for wedding events.

- The electric chafer base provides flameless burning capacity while its adjustable dial satisfies venues with rigorous fire regulations.

- Guests seeking sustainability will love induction warmers especially when used with appropriate frames because they deliver heat precisely without flames.

To stop burn damage maintain at least two inches of empty space between ceramic and burner units.

Maintain Steady Temperature During Service

The performance quality of ceramic chafing dishes reaches its optimum point when placed in an environment with surrounding steam.

- Add about 66% of near-boiling water into the stainless steel water container until it reaches two thirds of its capacity. The correct water level for the pan is essential to avoid charring the surface yet prevent water from getting overly high.

- Check water levels every 45 minutes and replace it with hot water rather than cold water to maintain thermal equilibrium.

- Lift lids only when plating. Steam from the chafing dish food will return to the dishes when the lid rests at a 60-degree hinge angle throughout continuous buffet traffic.

When stirring, fold from the edges toward the center. A slow folding motion in the dish allows heat distribution while ensuring that all parts of the dish remain above 140 °F (60 °C).

Professional Handling Tips That Make a Difference

Keep a loop of similar dishes moving continuously from serving station ends to compensate against draft exposure around doors and air vents.

- The frame should raise on a small riser in order to improve fuel can access to air thus avoiding accidental flameouts.

- A heat-diffuser plate protects the ceramic base from direct flame contact especially when burners near the base.

- Checking the gel fuel level midway through service is important because weak flames often appear when temperatures of food decrease.

Cleaning and Maintenance to Preserve Heat Performance

After service, patience pays off:

- Natural cooling of the insert should precede washing because a change in water temperature creates thermal shock.

- Residue removal should be done using baking soda paste or a non-abrasive cleaning pad but you should avoid steel wool for this task.

- Checks for tiny surface cracks named crazing should be routinely performed since these cracks indicate bacterial growth until it becomes time to replace the dish.

- The storage of lids should be maintained with paper towels or slightly opened positions to prevent moisture buildup which could trigger unpleasant odors.

Your ceramic will offer reliable service for many years when properly maintained because it can both stay thermally efficient and maintain its glossy appearance.

Quick Fixes for Common Heating Issues

- Rapid cooling right after setup? The prolonged heating time for the dish remained insufficient. Empty the dish and heat it using oven methods followed by replacing the fuel source with fresh material.

- Scorching on the bottom layer? The water in the ceramic cooker should be raised above its optimal level. Fill the pot with hot water after checking that the flame burns at a lower intensity.

- Hairline cracks appearing? When the burners cause issues check your distance settings then switch to a heat distribution-friendly electric heating system using milder fuel.

- Condensation making fried foods soggy? To allow steam escape without losing heat you should place a folded napkin near the hinge of the lid.